A friend asked if I wanted to transform this table and three chairs she was getting rid of. I didn’t hesitate to accept. Even though they were in a bad way, they have a charm I couldn’t resist. I’ve always loved bistro-type sets; they conjure up visions of outdoor dining in romantic European cities. It was only when I started work on them that I discovered they are 130+ years old and are a true gem.

Materials used: Rust-Oleum American Walnut stain, Varathane Dark Walnut stain, Rust-Oleum Rust Reformer, 1/4″ plywood, 1″ x 6′ red oak board, Rust-Oleum Satin Protective Enamel, Shellac, Varathane oil-based polyurethane.

A bit of a mess: The original, laminated plywood seats were either missing completely or damaged beyond repair. The paintwork was flaking and rusted. The table top was only being held together by the leg brackets and a makeshift brace, and the finish had almost completely worn away.

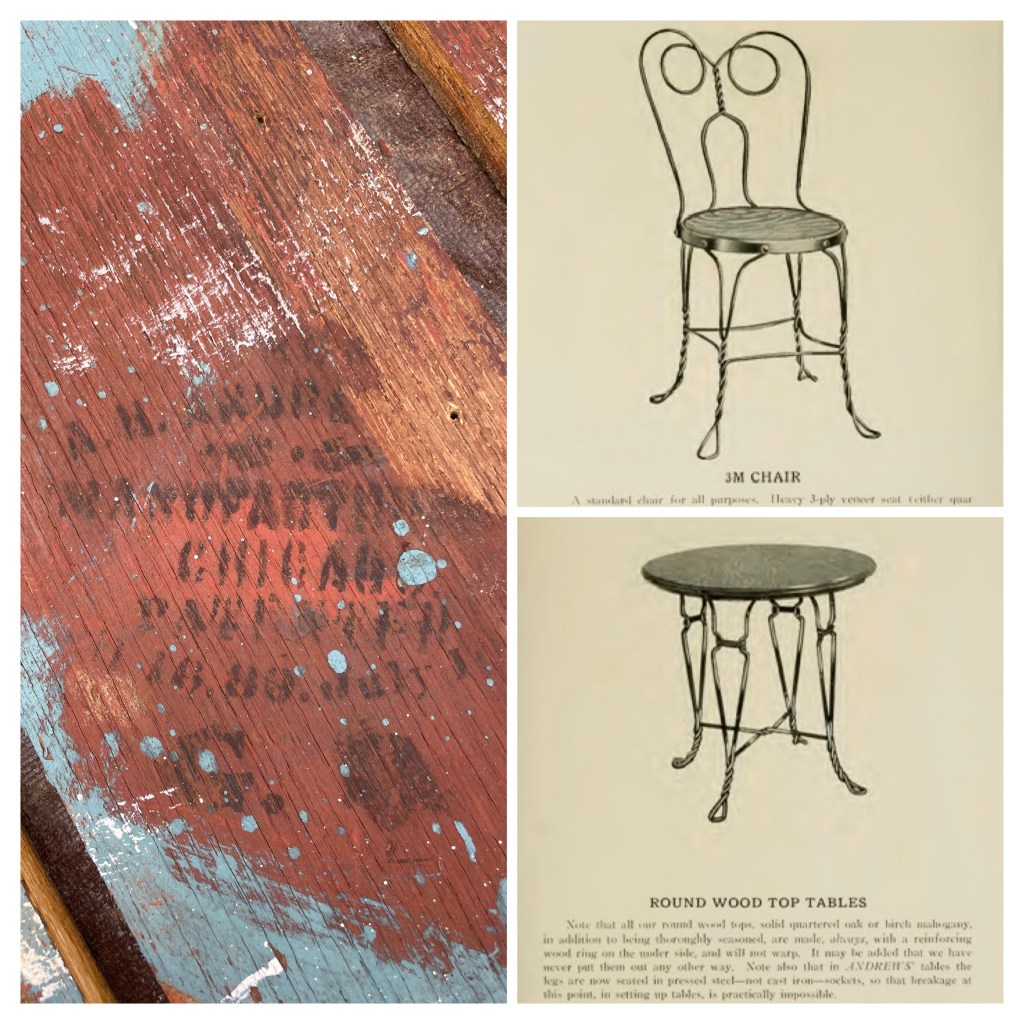

Researching the maker’s mark on the underside of the table revealed that this set was made in the late 19th-century by a company called A H Andrews of Chicago. In their catalog (where I found these images) they state that they made metal furniture for “Drug Stores, Confectioneries, Restaurants, Clubs, Billiard Parlors, Barber Shops, Shoe Stores, Offices and Reception Rooms”. This set is made of Bessemer steel and originally had a Japanese copper finish. The seats were laminated plywood and the table top was mahogany or quarter-sawn oak. When I read that another original finish option was white enamel, I knew I could paint with a clear conscience.

- Leg brackets and pine block holding the table top together.

- Separated table parts after removing the legs and block.

- Replacement reinforcing wood ring parts cut from new red oak.

- Glued, clamped and re-assembled table top.

Once the table top had been repaired I routed the edge of the reinforcing wood ring, removed all the old finish and stained both the top and the new wood ring with Rust-Oleum American Walnut stain followed by Varathane Dark Walnut stain.

It was then time to prep the steelwork by first removing any loose paint. What was going to be the most effective way? I looked into sandblasting and chemical dipping but they were expensive. I tried wire brushes, sandpaper, and my Dremel but that was fiddly. Then I remembered our 173cc pressure washer and turbo nozzle which will take the skin off your bones if you’re not careful. It worked wonders.

With a little help from Handy Hubby I took apart the pressure-washed chairs so I could cut, prime and install new plywood seats. Next I used a product I have used before on old metalwork that had signs of rust: Rust-Oleum Rust Reformer “instantly bonds with rust and transforms it to a non-rusting, flat-black paintable surface and prevents future rust.”

Once the chairs and table were re-assembled I applied 3 coats of Rust-Oleum Protective Enamel in shell white satin finish to all the metalwork.

Finally the stained tabletop was sealed with 2 coats of shellac and then finished with 2 coats of Varathane oil-based polyurethane in satin finish.